The Simple Beauty of an Innovative Bike Frame (and our 1st “Interview with an Inventor”)

In the eyes of this engineer there are few things as beautiful as a bike or motorcycle frame. Some are simple with all joints on display, others are complex and bewilder you as you try to interpret the movement and function of each component and how they work together.

Recently a bike frame patent application published that was the later. I stared and I read, trying to comprehend the beauty of it. Heck, I even Googled the name of the applicant, Level One Engineering LLC, to learn more, and that is rare. They do have some amazing designs.

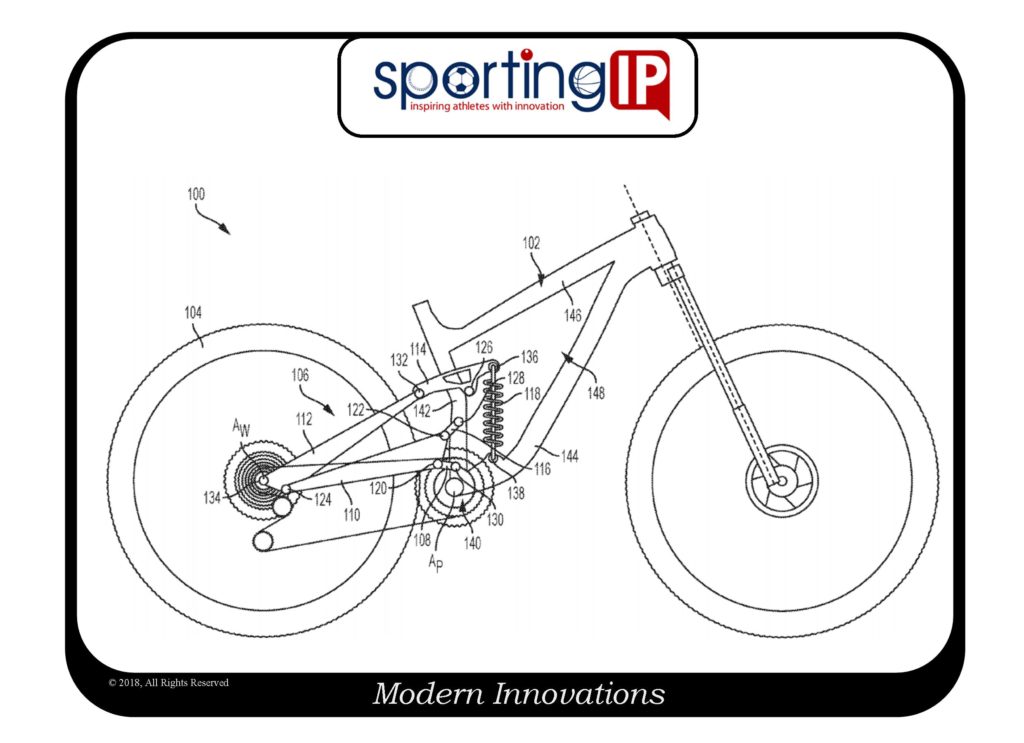

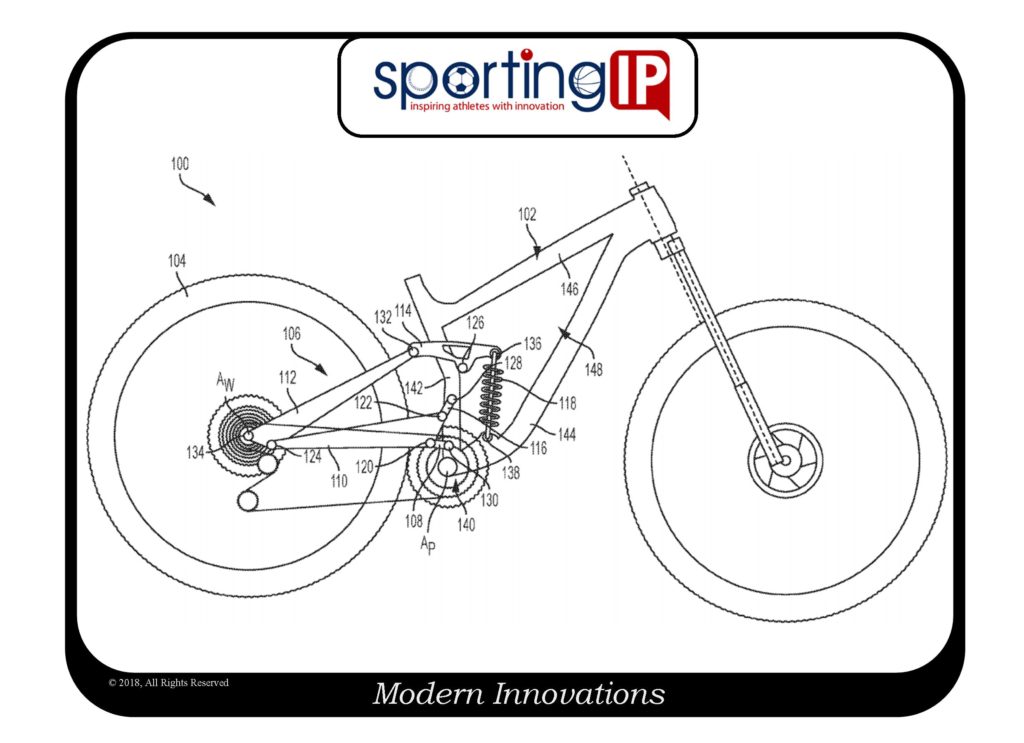

The application published as US Pub. No. 20180037295, which describes the invention as:

A bicycle may include a front triangle and a rear suspension system that couples the front triangle to a rear wheel and is dampened by at least one shock absorber. The rear suspension system includes a six-bar linkage having two ternary links separated from each other by one or more binary links, such that the two ternary links do not share a common joint. One of the ternary links may comprise a chain stay. In some examples, the other ternary link may comprise the front triangle. In some examples, the other ternary link may comprise a rocker arm coupling a seat stay link to the shock absorber.

The application explains:

[0003] A bicycle rear suspension system improves bicycle comfort and performance, particularly for mountain bicycles, by allowing the rear wheel of the bicycle to track the terrain to some extent. This improves rider comfort by reducing the jarring effects felt when passing over uneven terrain on a so-called “hard tail” mountain bicycle (i.e., one that lacks a rear suspension system), and improves performance by increasing traction between the bicycle and the terrain while pedaling, turning and braking.

[0004] Various bicycle rear suspension systems have previously been developed. For example, U.S. Pat. No. 5,628,524 to Klassen et al. describes a rear suspension system in which a pair of rotatable links connects the rear triangle of a bicycle to the front triangle and a shock absorber, in a manner resulting in an s-shaped travel path of the rear wheel as the shock absorber is compressed. U.S. Pat. No. 8,066,297 also describes a rear suspension system including a pair of rotatable links connecting the rear triangle to the front triangle and a shock absorber, in which one of the links changes its direction of rotation as the shock absorber is compressed, resulting in improved riding characteristics.

[0005] U.S. Pat. No 8,998,235 to Beale describes a rear suspension system in which three rotatable linkage members connect the rear wheel of a bicycle to the front triangle and a shock absorber. Systems such as these may be referred to as “four-bar linkage systems,” with the three linkage members accounting for three of the “bars” and the front triangle accounting for the fourth bar. Four-bar linkage systems may have rear wheel and pedal-related variables which are dependent upon variables related to the shock absorber. It may be desirable to have these two sets of variables independent from one another. Systems such as described in U.S. Pat. No. 8,988,235 to Beale may also have acceleration anti-squat values which are related to braking anti-rise values. It may be advantageous to have anti-squat decoupled from anti-rise. These variables and values are described in greater detail below.

[0006] One goal of a rear suspension system such as those described above is to provide a relatively firm response to pedaling inputs, as when ascending or riding on smooth ground, but also to provide a relatively forgiving response to bumps or terrain inputs, as when descending or encountering rough terrain. This reduces the unwanted loss of pedaling energy due to unnecessary shock absorption, while preserving the desirable properties of the suspension system. There remains significant room for improvement in this regard.

It goes on to further explain the benefits of six-bar systems:

[0043] In general, bicycle rear suspension systems of the present disclosure may include a six-bar linkage connecting a front triangle of the bike frame to the rear wheel. Links of the six-bar linkage may have varying lengths and arrangements. In general, a planar, one degree-of-freedom linkage in the general form known as a Stephenson chain may be utilized, with two ternary links separated by one or more binary links. For example, a so-called “Stephenson II” or “Stephenson III” topology may be utilized. Motion of the linkage may be dampened, e.g., by a shock absorber device coupled to one or more of the links.

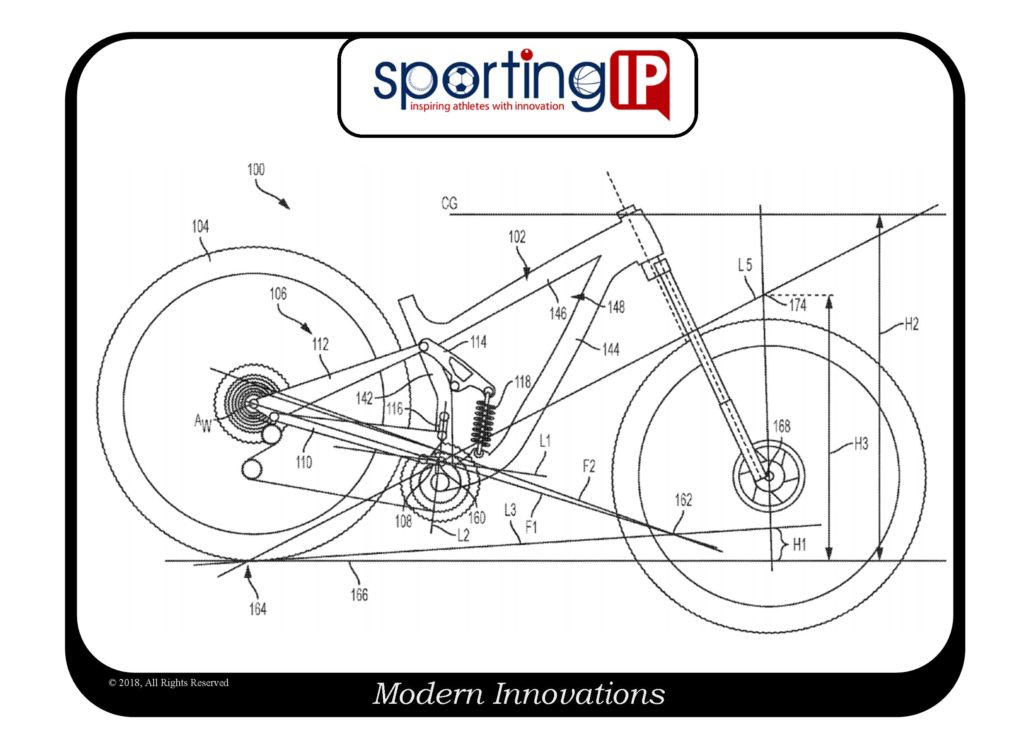

[0044] Use of a six-bar linkage in accordance with aspects of the present disclosure may provide an improved rear suspension as compared to other topologies. Typical four-bar suspension systems have an inherent dependency characteristic present in all of the tuned variables of the system. Specifically, in four-bar suspension systems, if one of the performance variables changes significantly as the suspension moves from full extension to full compression, then other variables will as well. For example, there is a relationship between dCSL and the shock rate, and there is a relationship between pedaling anti-squat and shock rate.

[0045] Six-bar systems according to the present teachings allow for greater separation of pedal performance variables from shock performance variables, essentially giving the system one characteristic for pedaling performance and a separate characteristic for shock performance. Because of the increased number of links in the linkage, it is possible to have high rates of change in chain growth (dCSL and d.sup.2CSL)–a desirable goal for pedaling performance–while having very linear (or at least monotonic) changes in shock rate/leverage ratio–a desirable goal for shock tuning. Accordingly, the shock rate can be tuned independently from dCSL and independently from the anti-squat.

[0046] Because there is separation between pedal performance variables and shock tuning variables, it is possible to adjust the geometry of the bike (primarily by changing the position of the rear axle relative to the bottom bracket) without making changes to the shock rate. Geometry can be adjusted more easily for different sizes of bikes without changing key kinematic relationships of the suspension system.

Pretty amazing frame!

Dave Dawsey – Monitoring Cycling Innovations

PS – follow me on Twitter (@sportingIP) and please sign-up to receive posts via email.

Interview with an Inventor Series

The inventor, Luke Beale of Level One Engineering, was kind enough to answer a few questions for us:

Tell us about your background and how you ended up designing bikes.

I’m a mechanical engineer. I worked in bike shops when I was in college, but was always interested in the more analytical side of engineering. I became a bike engineer because it allowed me to work on complete projects that require high level engineering but also an aesthetic sense. Bikes are high performance consumer goods, so they have to perform at a high level, be strong and light, and look great. All of those features make them interesting from an engineering point of view.

Tell us about the origins of your company Level One Engineering and who are your ideal clients.

Level One Engineering is an engineering consulting company focused on the bike industry. We handle projects from initial concepts through production, with a specialty in full suspension frame development. We work with companies large enough to need engineering help and small enough that they don’t have specialists in house. We also develop IP outside of projects for clients.

As a prolific inventor, what advice do you wish someone had given you as a young creative engineer?

I actually got really good advice as a young engineer. I would say the best advice I can offer is to follow your passion – if you work in a field you care about, it doesn’t feel like work.

Where do you look for inspiration in your designs?

For ideas on new suspension systems, my inspiration comes from mathematical modeling. I trust high level math and physics and look for new ways to analyze and model the system.

What do you consider the greatest innovations in cycling?

The biggest innovation recently has been the elimination of the front derailleur. There is so much more freedom allowed in frame design when you don’t have to worry about how to make them fit…

What new technology/technologies are you most excited about (whether in the field or not)?

I think electronics are going to become an accepted part of cycling – control systems for suspension are on their way. I’m more excited about 3D printing for on-demand manufacturing more than anything though. I think it’ll really change the industry.